Our Capabilities

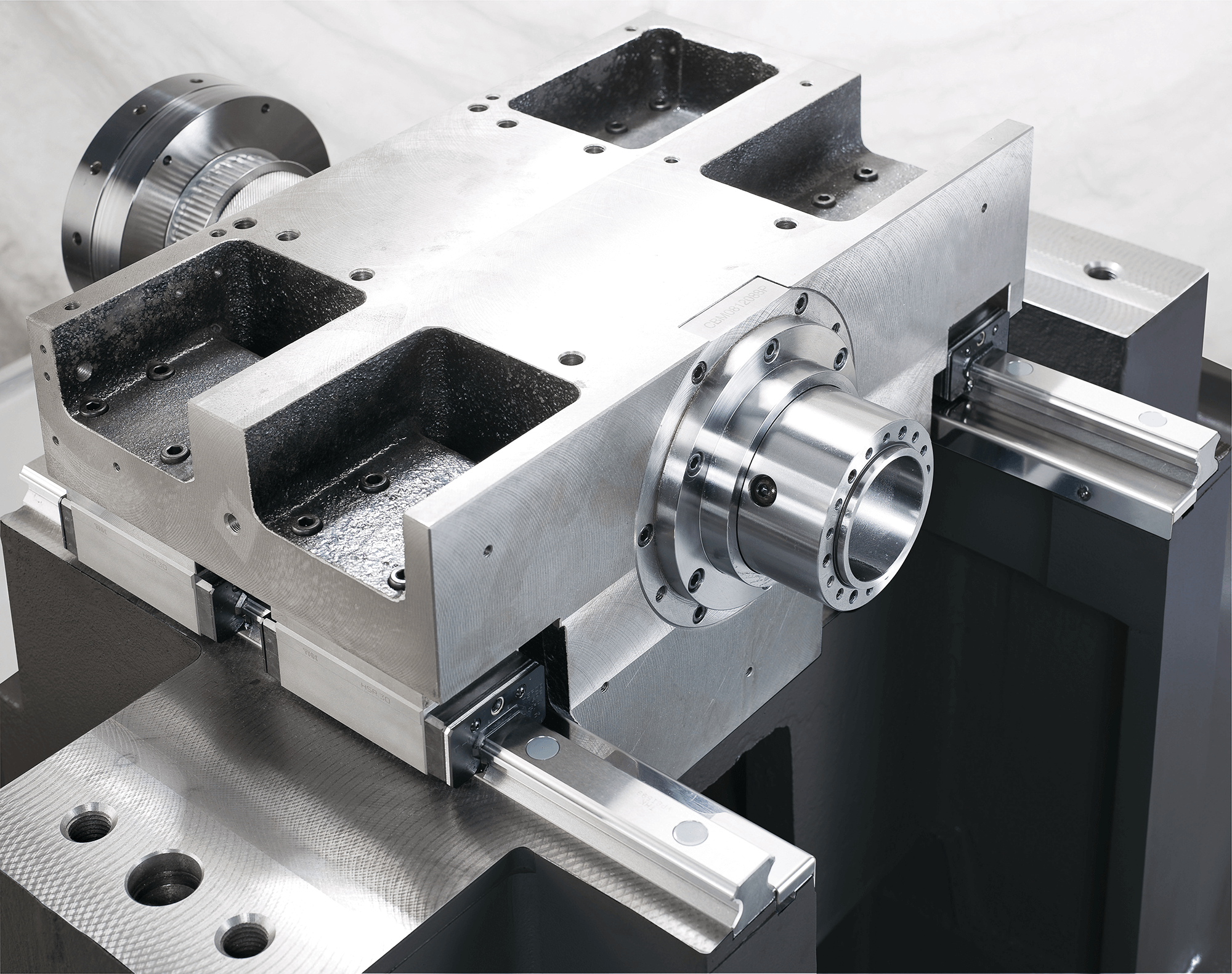

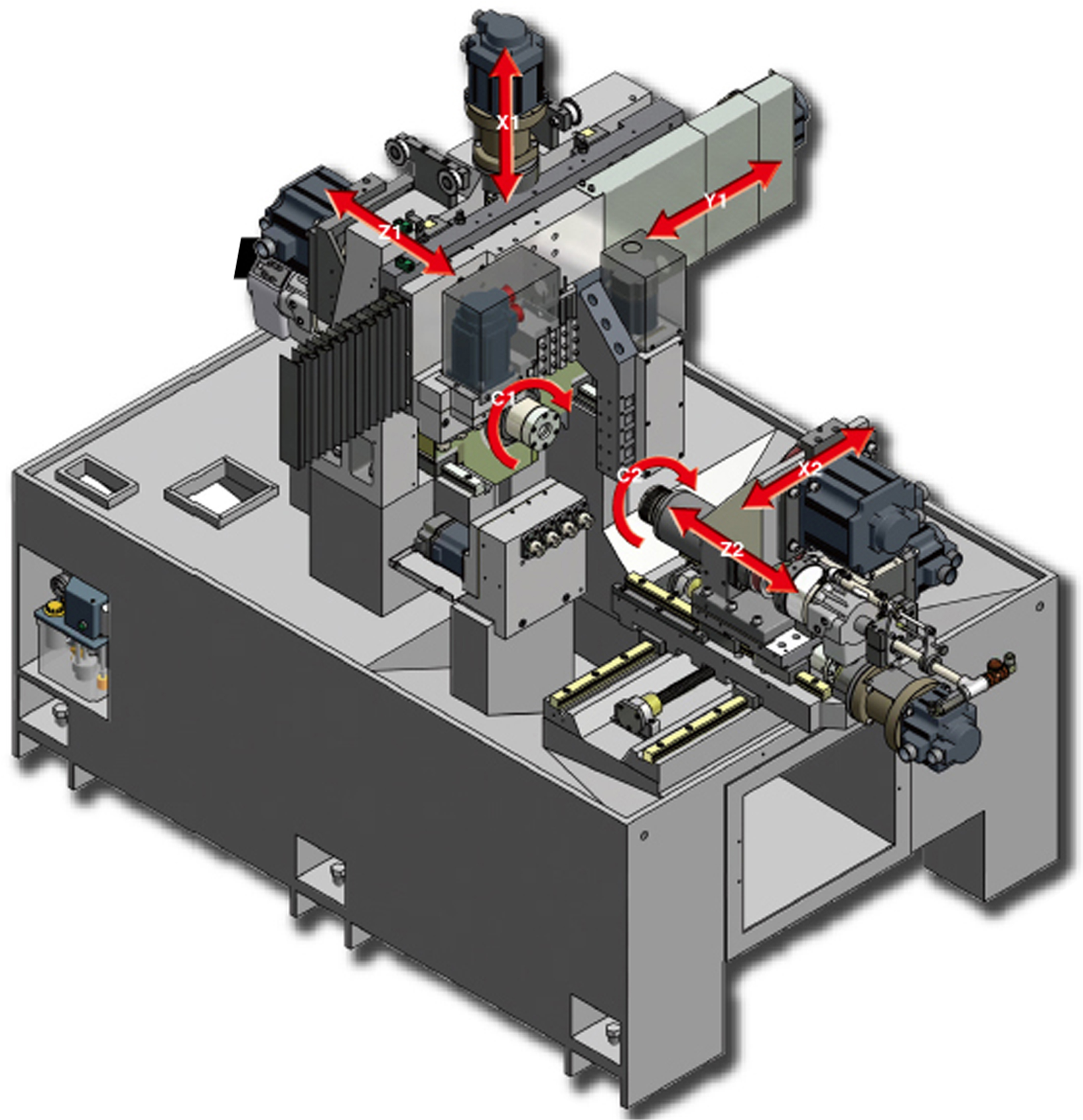

Action Engineering Corp. provides a service featuring our state of the art 7-Axis CNC Swiss Screw Machines without guide bushings, that enable us to start with round bar into bar feeder, then off the machine into the parts catcher in one complete operation! Our machines boast capabilities including Dual “C” Axis and “Y” Axis with 19″ Travel, 27-Tools with 11-Driven Tools, Simultaneous Main & Sub-Spindle Machining, Tool-Load Monitoring with Cutter Torque Sensing, 36mm 1-3/8″ Bar Capacity, 1,181 Inch per Minute Rapid Rates, Bar Feeder for 12′ Long Bars, High Pressure Cooling System.

We use AutoDesk Inventor software for building solid models of parts, and also AutoDesk Partmaker programming software for Swiss Machines. This enables us to program and run the most complex parts, hold tolerances, and get accurate run times.

We can produce a diversity of products for our customers. We have an experienced staff capable of providing for the aerospace, industrial, entertainment, medical, commercial, and government industries. We specialize in long run production orders. It is our desire to form a team with our customers, providing, on-time delivery, quality products, and best pricing.

Hi, my name is Gary Goldner, and I want to introduce myself. We are a machine shop specializing in CNC Swiss Machining. We have 600-1200 hours per month current capacity on our screw machines. We use Autodesk Inventor Software for Solid part modeling, and Autodesk Partmaker for Swiss Machines to do our programming. This enables us to make very complex parts in one operation, as our machines are multi-axis, multi-spindle 7 axis machines with 27 tools.

Hi, my name is Gary Goldner, and I want to introduce myself. We are a machine shop specializing in CNC Swiss Machining. We have 600-1200 hours per month current capacity on our screw machines. We use Autodesk Inventor Software for Solid part modeling, and Autodesk Partmaker for Swiss Machines to do our programming. This enables us to make very complex parts in one operation, as our machines are multi-axis, multi-spindle 7 axis machines with 27 tools.

I have successfully operated or been in key positions in 3 other companies which have been registered to AS9100. Recently, I sold my last company and established Action Engineering to get into the screw machining business. My other companies consistently maintained very high OTD & quality ratings, which gained us the loyalty of prime aerospace/defense contractors such as Boeing, Lockheed Martin, Raytheon, SpaceX, & ULA. I know how to run a tight ship and smoothly deliver results. I would appreciate an opportunity to quote on work for you.

We are operating under AS9100 guidelines, and we are working on our AS9100 registration. We are accountable for our commitments & actions; we are honest in all our transactions. We are proactive in planning smooth processes but if things go off-course, we focus on getting back on track. We do not make “our problems” the costumer’s problem. We expect and support competent and skilled teams. We set high goals and remove barriers to their achievement. We maintain a positive work environment for all our employees, so they may work in confidence that they are respected and valued.

Thanks,

Gary Goldner (Founder & President)